THIEME

Using synergies: Environmental and energy management in interaction

When THIEME introduced an energy management system in addition to the environmental management system in accordance with ISO 14001, it was clear that the first step had to be to know the energy consumption.

With around 350 employees, the internationally active family business THIEME has two sites in Teningen (Baden-Württemberg). The Tullastrasse plant manufactures plastic molded parts such as housings and cladding, functional parts and system solutions as well as safety, decorative and comfort parts for the automotive industry, while the Rohrlache plant produces screen printing and digital printing machines for industrial printing.

In 2022, when the energy crisis was dominating the news, shortages were looming and energy prices were rising, THIEME knew its energy consumption from the energy supplier's monthly bill and manual readings. Julien Simon, responsible for environmental and energy management at THIEME, was aware that it was not possible to determine targeted efficiency measures on this basis. In order to achieve greater transparency, he looked at a few energy management systems. The choice fell on econ, "not only because I knew it from my previous job, but also because it offers great visualizations and evaluation options," says Simon.

Funding for energy management system

With information on the scope of the project and an indicative offer, Julien Simon submitted an application for funding in accordance with the Federal Funding for Energy and Resource Efficiency in the Economy (EEW). As part of module 3, measurement and control technology (MCR), sensor technology and energy management software are subsidized by up to 45%, depending on the size of the company.

After receiving the positive funding decision, the installation of the system began. Together with the technology service provider and electrical wholesaler Alexander Bürkle, who is also a partner of econ solutions and has the products in its portfolio, THIEME set up the system so that the pulses from the existing meters are recorded and automatically imported into the econ4 energy management software. In addition, some new measuring devices were installed at the important sub-distribution boards and also integrated into econ4. Measuring points for which it is sufficient to know the monthly values are still read manually and the data entered into econ4.

Mobile measurements for more depth

THIEME also uses the mobile measuring system econ case. "This allows us to record the energy data directly at the systems as required. This is because we don't have to take continuous measurements there; a specific time interval is sufficient," explains Julien Simon. He has also drawn up a measuring point plan according to which all systems are successively measured. "Once we have implemented a measure, we measure the system again to check whether we are actually achieving the desired effect." The econ case is also used if unusual consumption is registered in a sub-distributor in order to go into depth and check which system is responsible for the consumption.

Big leverage: the base load

However, the environmental and energy manager started with the biggest lever in the electricity sector: the base load. This is made up of many factors, and one important starting point was the electricity-based mold temperature control for plastics processing. Although the pumps for providing the temperature control were switched off if they were not needed for a longer period of time, the boilers were kept at a constant temperature. Based on the measurements, it was determined that a new heating phase is more cost-effective than continuous control of the boilers. This enabled the time settings to be optimized and electricity consumption to be reduced.

Julien Simon is currently implementing measures to reduce peak loads. "Of course, the evaluation from econ also helps us with this," says the environmental and energy manager.

High savings with natural gas

THIEME achieved the greatest savings with natural gas. "This is mainly due to the fact that we only have a few large systems here, whereas electricity consumption is spread across many more small consumers," explains Julien Simon.

Gas consumers are, for example, the heating systems in the various buildings. These had been running for years according to the basic settings, i.e. until 10 p.m. in the evening, as is usual in residential buildings. However, as employees usually leave the company by 6 p.m. at the latest, Simon adjusted the setting to 5 p.m. and new smart thermostats were also installed.

Natural gas is also used to heat the air in the paint shop. To increase efficiency here, THIEME invested in an air recirculation system: instead of releasing the heated air completely outside each time and reheating fresh air, only as much as necessary is now replaced by fresh air so that the majority of the heat remains in the system.

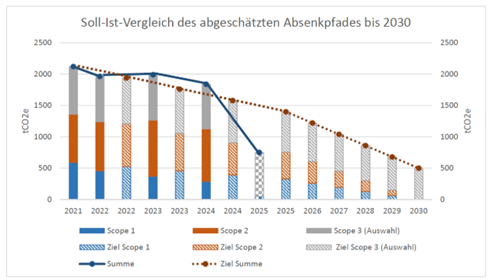

Decisive contribution to achieving the climate target

Compared to 2021, THIEME was able to reduce its natural gas consumption by over 50% in 2023. Overall, the energy efficiency projects have led to a reduction in consumption of around 1,200 MWh of electricity and gas per year - an important contribution to achieving the climate target: THIEME wants to reduce its CO2 emissions to zero by 2030. A comparison of the CO2 reduction plan (Scope 1 to 3) with the expected results from the measures already implemented shows that THIEME will significantly exceed its target for 2025.

In-house electricity generation using a PV system and the purchase of green electricity and green gas also contribute to this. One system was already installed in 2015, and further systems are planned for two hall roofs. And further energy efficiency measures will also follow. "These would not be possible without the current energy data, evaluations and comparisons," explains Julien Simon.

"My favorite features in econ are the many evaluation and comparison options - and that you can have the most important ones automatically sent to yourself and others as regular reports."

Julien Simon, Responsible for environmental and energy management at THIEME